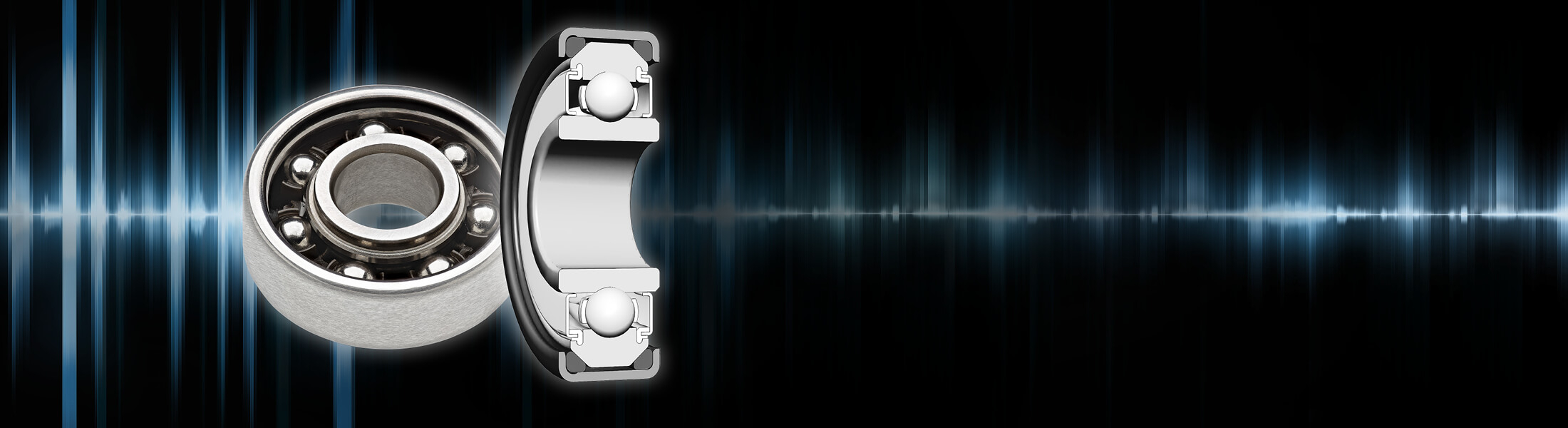

NVH Bearings

Passive structure-borne sound isolation reduces noise emissions

The current trend is towards e-mobility. However, with the electrification of vehicle drives other challenges have arisen. For example miscellaneous power units such as air conditioning compressors and brake booster systems generate vibrations from which unpleasant noises can result. Previous solutions have been restricted to very high accuracy in the manufacturing process and the use of specialised lubricants to reduce the running noise. Unfortunately, this helps little against vibration and structure-borne sound being converted to airborne sound.

The wiser choice is NVH (Noise Vibration Harshness) bearings from ROLLAX, that thanks to passive structure-borne sound isolation, can reduce noise levels by as much as 10 dB(A).

An insight into noise generation in motor vehicles.

For those who wish to reduce interior noise levels in motor vehicles must first understand how these noises develop. At this point it is important to differentiate between structure-borne and ultrasonic noise. Structure-borne noise is not audible to us. It is created when a solid body vibrates. An example would be the shaft in an electric motor or a transmission. Where these vibrations meet a resonance body such as the coachwork, door panel or the vehicle bulkhead they are transformed into audible sound. Where the resonance body is positioned near to, or has a rigid connection with, the passenger compartment this is perceived as an annoying noise.

ROLLAX NVH bearings allow an acoustic decoupling of the vibration generator and the resonance body. The acoustically tuned bearings therefore inhibit the transformation of structure-borne noise to airborne noise preventing the problem at point of origin.

A typical application: specialised bearings for servo brake systems

The servo brake system is usually mounted on the bulkhead in front of the brake pedal between the engine and passenger compartment. This permanent connection to the pedal allows the vibration to be transferred to the passenger compartment causing irritating noises. Up until now the solution involved an optimisation in vehicle design. This concept failed because the rigid body of the car and the bulkhead form an ideal resonance body which inevitably transports the vibration into the passenger compartment.

In the ROLLAX recommended decoupling of the vibration generator, by means of an acoustically matched specialised bearing, vibrations are absorbed using a temperature resistant elastomer before they reach the vehicle body. For the best possible adaptation of the NVH bearing to the specific application, ROLLAX analyses the frequency input in order to determine the necessary attenuation parameter. The technology is very flexible and can be adapted to many frequencies and surrounding vehicle parts. The ratio of absorbance to rigidity is also adjustable within the application.

Our ready-to-fit NVH bearing conforms to all normal standards. It requires no additional space and as it is, in size and function, compatible with all conventional bearing standards it can be seamlessly integrated into all manufacturing processes.

Quietly into the future with ROLLAX specialised bearings

Electric drive systems will play an ever increasing role in the future. The significance of NVH bearings in modern mobility will therefore increase proportionately. Extremely low noise emissions, in the passenger compartment, have become a key factor for comfort. As such the optimisation of background noise levels, in motor vehicles, will be of ever greater importance. Our acoustically tuned specialised bearings help you to solve tomorrow’s challenges, today, securing your competitive advantage.