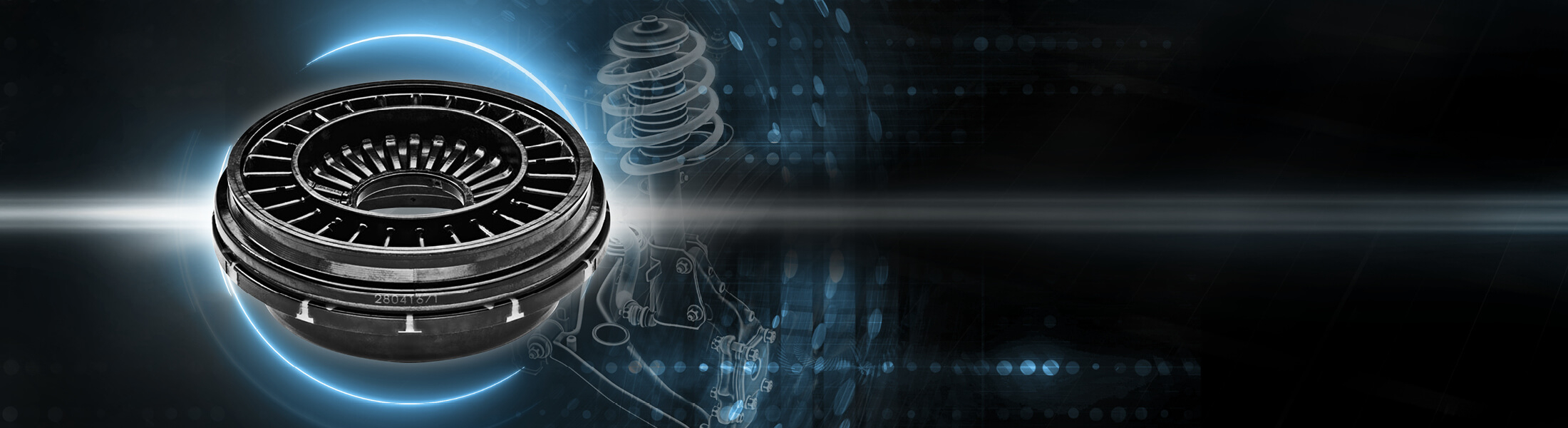

Suspension Strut Bearing

High-quality components for the best driving characteristics

The suspension strut bearing is an integral part of the chassis in modern motor vehicles using MacPherson front axle strut-type suspension. The bearing decouples the spring from the vehicle body enabling the suspension strut to pivot when steering. As such the strut bearing plays a hugely significant role in the car handling characteristics. As a specialist, in plain and ball bearing technology, ROLLAX manufactures individual suspension strut bearings that satisfy the most exacting standards of quality, reliability and longevity.

The task of the suspension strut bearing

As the wheels of a motor vehicle turn when the steering angle is altered, it is necessary for the connection to the front axle to allow torsional movement. In the 80% market share that use MacPherson front axle systems, this is accomplished with the help of a top-mount and suspension strut bearing combination installed together.

The top-mount is usually a sturdy rubber-metal element below which the suspension strut is mounted. In modern motor vehicles usually an angular contact ball bearing. The malleability of the rubber in the top-mount enables small angular changes and also serves as a vibration absorber. The suspension strut bearing allows full torsional movement.

In spite of the inconspicuous nature of this component the choice of the most suitable bearing and the precise and accurate installation are extremely important to the faultless function of the suspension strut.

The more sophisticated and sport tuned motor vehicles increase the lateral forces on the suspension strut, which in turn convert to radial loads on the strut bearing. Although the axial burden, determined by the vehicle weight and the dynamic contact forces, remains the main burden, the radial load is gaining significantly in importance. Previously employed thrust bearings are being replaced by better suited angular ball bearings.

ROLLAX have always been pioneers. Not only were we the first manufacturer, worldwide, who integrated specialist plastics in the suspension strut, saving weight. We were also the first to introduce angular bearings into the suspension strut. In addition the permanent contact seal, enabling a lifetime operation of this important chassis component, was invented and patented by ROLLAX.

Suspension strut bearings enable low friction, precise torsional movement and guarantee smooth, precise steering and wheel reset.