Linear Bearings

Implementing low-friction linear movement

Linear bearings are a distinct type of ball or needle roller bearings which exhibit no form of circulation. In contrast to conventional rolling elements they are not designed to accommodate rotating bodies, but rather low-friction guidance of linear movement along a cylindrical shaft or other structural element. The usual classification in fixed or floating bearings, as is the case with linear ball bearings and linear needle bearings, does not occur.

Characteristics and types of linear bearings

Roller bearing based linear systems utilize rolling elements such as balls, rollers or needles to reduce the level of friction between the individual elements of the guide rail. This succeeds mainly due to a minimal point of contact or a line of contact between the supporting rolling elements of the bearing and the shaft, whereas – in contrast to slide type bearings – no relative motion between the friction partners occurs. In addition anti-corrosion, adhering lubricant enables the manufacture of very low friction and noise free linear systems.

Telescopic guide rails

These flat, lightweight linear guides are ideally suited to limited stroke applications. They consist of two rows of rolling elements running between an outer and an inner rail. The rolling elements are mounted inside a cage which holds them equally distanced ensuring a low level of friction.

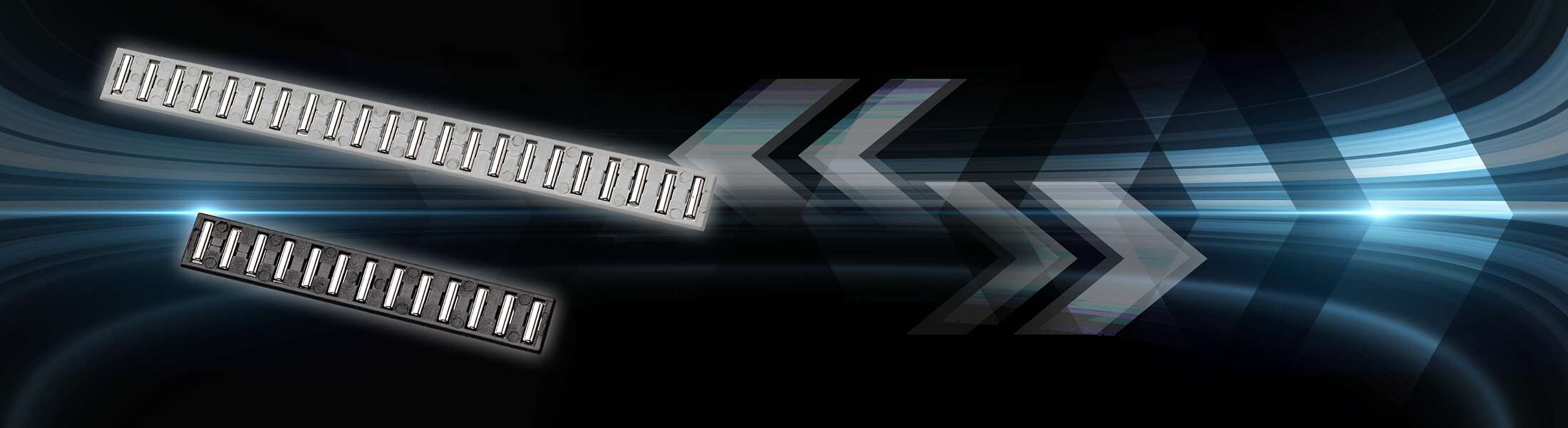

Cage guide rail

The cage guide rail consists of a pair of rails with a cage containing rolling elements between them. Due to the lack of a rolling element return function it is suited only to limited stroke applications.

The cage guide rail is available populated with balls or needles. In the case of ball bearings, available as two-point or four-point contact, between raceway and ball, depending on the version. While the two-point version only absorbs forces from the direction of the rail, the four-point version can also absorb lateral forces.