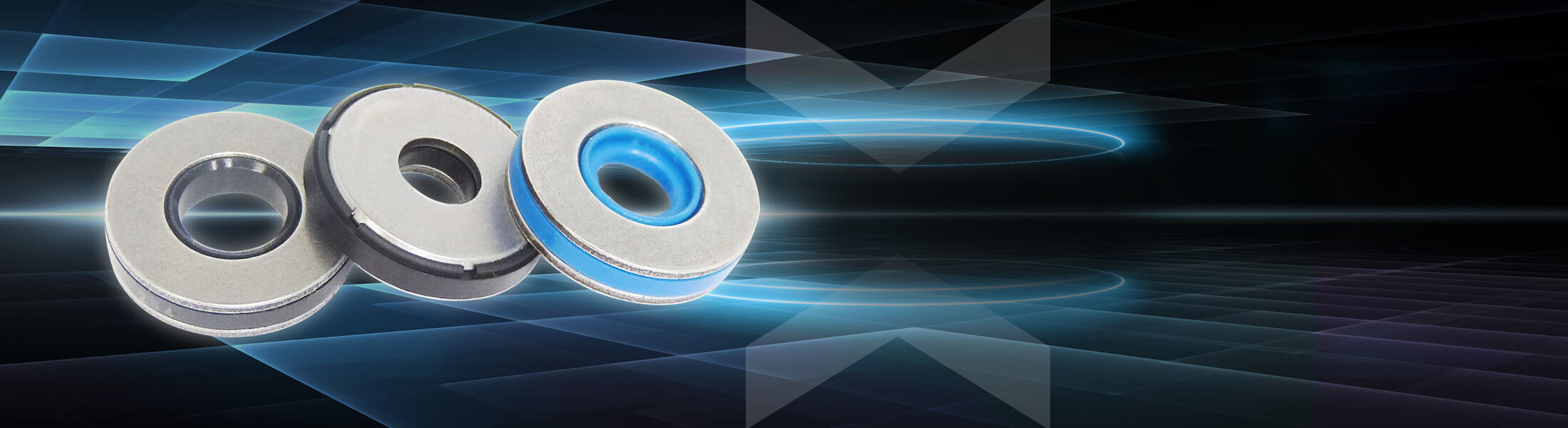

Thrust Bearings

High-quality rolling bearings for axial loads

The vast majority of electric actuators and worm drive motors use thrust roller bearings in order to counteract the opposing force of the worm drive. This is the case, in particular, with parking brakes (EMPB), electromechanical brakes (EMB), but also in hatchback (tailgate) motors.

The thrust needle bearing or the thrust roller bearing effectively prohibits the shaft executing axial movement, which would be detrimental to the application.

ROLLAX provides ball or needle thrust bearings, with or without thrust washers. The thrust washers are supplied, if so desired, lubricated and sealed, ready-to-fit.

ROLLAX thrust needle bearings designed to be able to absorb high axial and impact forces. To this end we have developed a very reliable rolling element that distinguishes its self in the following features:

- furnished with thrust washers,

- able to absorb high dynamic and static forces,

- minimal space requirement,

- lifetime maintenance free through the use of specialized lubricant,

- customizable.