One-way bearings

One-way bearings and their use in the New Mobility

Hybrid power trains consist of a combustion engine and an electric motor which means space under the vehicle bonnet is at a premium. In addition auxiliary hybrid systems such as oil and climate control pumps are needed. Such challenges are best faced with ROLLAX specialized bearings tailored exactly to the needs of your application.

One-way bearings from ROLLAX– The experts in bearing technology

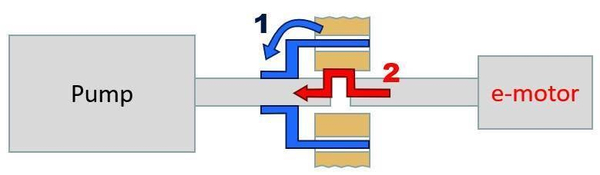

One-way bearings from ROLLAX, aka anti-reverse bearings or clutch bearings, are suitable, among other things, for power splitting devices which are supplied from two different power sources. This could be a pump that is powered either electrically or by a combustion engine – as illustrated in the chart below.

The one-way bearings are designed in such a way that torque is transmitted in only one direction. Allowing free motion of the drive in the opposite direction, and so transmitting force to the auxiliary device.