Gearbox Components

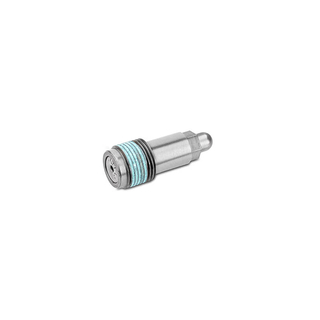

ROLLAX gearbox components, marketed under the brand name RJS, can be found doing duty in gearbox domes and gearbox assemblies in numerous vehicles from major motor vehicle manufacturers. Longevity and manufacturing precision are the hallmarks of our gearbox components. Our range of threaded detent pins and detent bushes as well as our assortment of detent sleeves are, without exception, designed for high-performance operation. The rolling characteristics and spring characteristics guarantee a firm, yet precise, gear shift feeling. Press-fit or threaded solutions enable flexible design of sub-assemblies. We also manufacture ball sleeves for the low-friction longitudinal movement of selector rods. The most recent example of our innovative gearbox component design is the sensor detent which allows connection to the serial interface of the vehicle control unit permitting transmission of the selected gear data.

Collective ROLLAX Know-how for your gearbox components

A globally established supplier to the automotive industry we design and test our components in-house. Machines and proprietary equipment for manufacturing and assembling the products are also predominantly built in our own specialist engineering department. In this way we can maximise our ability to adapt to specific customer requirements for gearbox components. Our exacting quality standards in purchasing, design and manufacturing provide, for our automotive industry customers, the certainty of receiving high-quality, fully tested gearbox components. We are externally audited and certified under DIN ISO TS 16949.