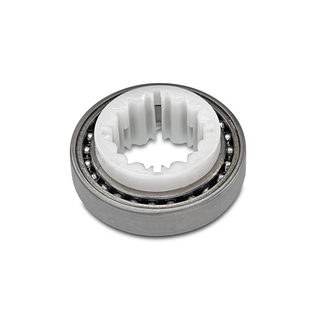

Ball bearing solutions manufactured by ROLLAX are specifically tailored to the customers applications.

What comes to mind when you hear the expression bearing, combined with car manufacturing? In most cases the answer is “wheel bearing” - that pioneer of automotive manufacturing. The wheel bearing is though, by far, not the only bearing in the power train. Between the engine and the wheels there are countless places, equipped with bearing technology. For instance: manual and differential gears with angular ball bearings, self-aligning bearings, 4-point ball bearings and thrust bearings. The driving force in the power train remains the engine. But, in order for the engine to function impeccably, further auxiliary units such as the alternator and pumps are necessary, and they are, of course, all equipped with bearings and one-way clutches. ROLLAX provides, as a manufacturer, a high degree of design support for needle bearings and one-way clutches, specialised and bespoke bearings.

The bearings named up to now all belong in the category, high rotational speeds. Not unexpectedly, bearings such as ball or needle bearings are also required for slower motion sequences. Here the focus is on the deliberate use of low friction bearings to introduce some comfort into the steering, gear-changing or making adjustments to the seating position.

For all of these fields of operation we have standard solutions and component parts in our portfolio. Where the standard solutions are insufficient to the task and individually designed bearings are necessary, we draw on the skills and expertise of our in-house design department, highly qualified and experienced engineers and technicians, who will design the tailored solutions you require and accompany you from a very early design stage right up until a suitable production line is in place.

For the growing e-mobility sector we also have solutions. Among other things we manufacture dedicated solutions specifically for hybrid-drive and start-stop systems. In this regard we support a number of well-known OEM and Tier 1 suppliers.

An important resource during the design and development phase is the professional accompaniment. Our in-house pivotal skills and knowledge in prototyping, simulation, toolmaking, experimental engineering etc. ensure that we mutually benefit from this resource.

ROLLAX, as an expert and manufacturer of bearings and motion technology, has enjoyed the trust, recognition and respect of the international automotive industry for more than forty-five years. Our experience combined with the very high standards in the automotive industry are also greatly appreciated by our non-automotive customers with whom many of our motion elements are represented. Perhaps even in a window in your home.